The Ocracoke 24 is the newest family member of the distinctive Carolina Sports Fisherman style of boats which this office designs for several of the local builders. It has all the sexy appeal and performance of those boats, but in a much smaller package and without the usual six to seven figure price tag.

The hull shape and general appearance are closely related to the flavor of the bigger boats, most distinctively the sheer and the flared bow, which has been scaled to a more sophisticated proportion.

The 24 is a larger, but not exactly scaled up, version of the 20. The beam has been drawn to 8′ 6″/2.59m, which is the maximum trailerable width in many states. The free board was also raised, but the (bottom) dead rise has been kept the same.

The picture of the finished boat here (temporarily) is of the Ocracoke 20. At this time, as this is a very new design, there have been no 24s completed and launched. There are several under construction, and you can follow the building of one of them on the B&B builders forum (see the link at the bottom of this page). As soon as we have pictures of a completed boat we will be posting them on this page.

|

LOA………..24′ 0″ 7.32m LWL………..19′ 7 1/2″ 5.98m BEAM…….. 8′ 4″ 2.54m DRAFT/ hull.. 9 1/2″ 24.13cm @ dwl DEADRISE at transom… 13 degrees HORSEPOWER…… 90 – 200 BOAT WEIGHT including 150 hp motor…2000-2400# (900-1100 kilos) depending on materials and options* DISPLACEMENT 2400 lbs (1100 kilos) @ dwl Pounds/Kilos Per I” /25mm immersion 482# (219 kilos) *weight @ designer’s suggested materials; different plywoods plus different fiberglass weight and optional gear will change boat weight. |

Photo at right by Wave Crest Images www.info@wavecrestimages.com Photo at right by Wave Crest Images www.info@wavecrestimages.com |

| The boat is cold molded plywood, built over a jig. Most of the “jig” becomes permanent structure. The construction employs a modified orange crate method that is both light and strong. Note that this boat is aimed at efficiency of materials for performance, but is not a stitch and glue “introduction to building” type of boat as built from plans which includes full size patterns for the “jig”. This model would also be an excellent choice for the small commercial yard. |

|

|

|

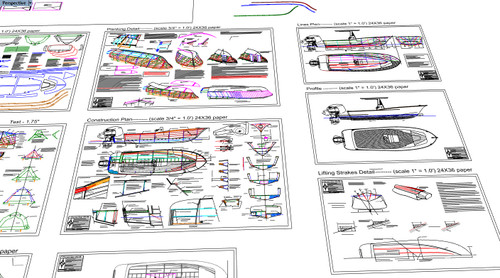

The full size templates are shown above.

There are full size Mylar* templates for the hull framing parts. Included are: Stem and keel; temporary frames, permanent frames/doublers; bulkheads; transom and transom arc; bottom stringers. The frames and bulkheads and drawn with the notches located and sized for the side stringers. Each of the parts is color coded: Examples: bottom stringers – blue; temporary frames-green. The drawings are 1/2 of each frame, transom etc.. When tracing your parts on the wood you will simply flip the patterns. The use of the template patterns eliminates any need for lofting and ensures that your framework will be accurate and true. It is also much quicker and easier.

*Mylar is drafting film, which while it is quite expensive, is totally stable and practically tear proof. It is practically transparent, making it easy to orient on your plywood grain and allows for it to be used for both sides on one sheet. Halving the Mylar pattern drawings saves a lot of shipping weight.

As can be seen from the top picture at left: The first and third frames are temporary as well as the frame sides. All of the rest of the structure stays in the boat. The forward sheer clamp has one of its four laminations installed. There are two stringers to be installed between the intermediate sheer and forward sheer clamp to complete the hull framing.

The bottom is planked with a layer of 3/8″ (9mm) and a layer of 1/4″ (6mm) ply with staggered seams. The sides are planked with two layers of 1/4″ (6mm) ply. The side planking uses the Ashcroft method which means both layers run diagonally in the same direction, the seams in the two layers are staggered.

The entire boat is epoxy glassed inside and out with one layer of 1208 biaxial glass cloth which makes for a very strong tough boat. The complete encapsulation of the wood creates a very low maintenance and a long-lived boat. The boat is painted with epoxy primer and the top coat is two part polyurethane paint.

Built as designed, the owner will have no more maintenance than a production built polyester boat.