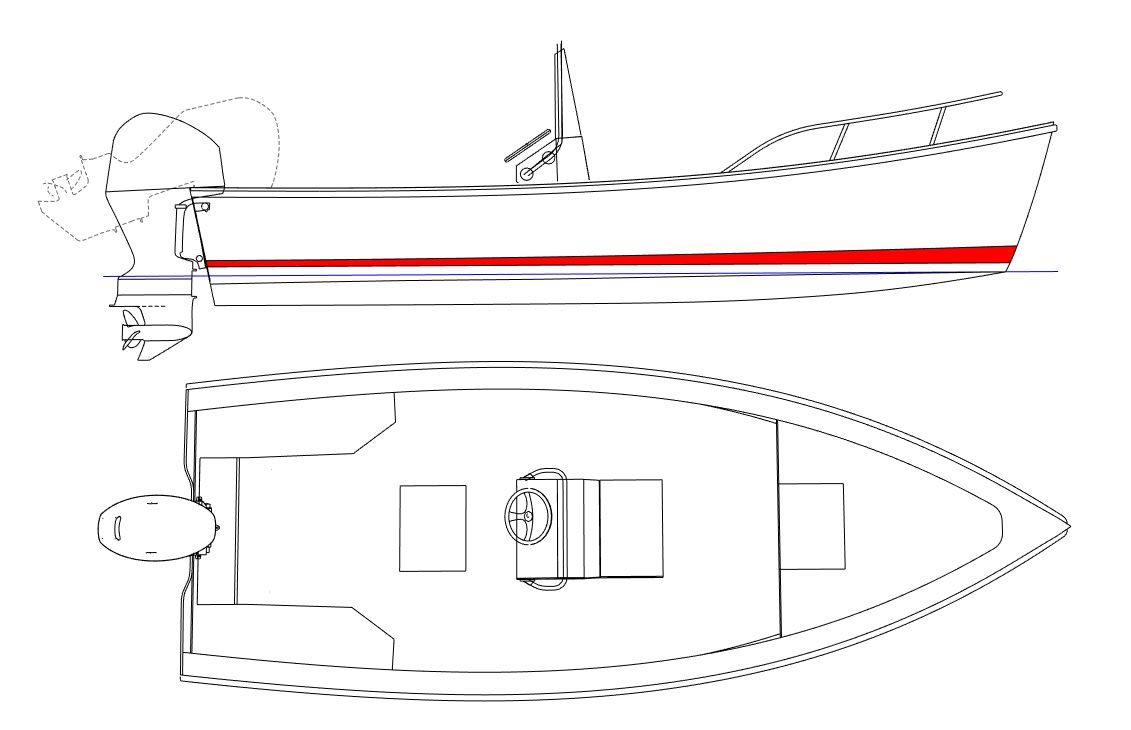

Jessy 17'

Pictures: Jessy 17 Hull #1 Jessy 17 Hull #2

The Jessy 17 was born at the request of a builder in Graham's boat building class as a larger version of the Jessy 15. She is a simple plywood skiff that can take up to a 50hp motor.

She has a 10 deg v-bottom suitable for a inland waterways and light chop. Hull #1 performed very well. For Hull #2 we made her even easier to build and added a cockpit sole. The cockpit is NOT self bailing but there is room under the sole to route the steering and fuel line from the console. Sealed, foam filled buoyancy chambers in the stern and bow provide flotation.

The Jessy 17 is currently available as a CNC kit only.

Specifications:

Length: 17'

Beam: 6' 6"

Deadrise: 10 deg

Draft: 8"

Displacement: 1400 lbs

Max HP: 50hp

Cockpit depth: 23"

The Hull is folded and stitched together upside down. Bottom stringers slid into the bottom panels and are held tight to the bottom with tabs and wedges.

Then the hull is then flipped upright into cradles and a keel pad is glued down and the chines and transom are glassed.

Below, the interior is glassed, side stringers and inwale are installed.

Then the hull is flipped upside down, sanded and glassed. A layer of microspheres over the glass if applied for fairing and the keel is glued down.

The boat is flipped back upright after sanding the bottom. Control conduit is fitted, cockpit sole is installed, stern seat boxes are installed and the carlins (1x4) are bent into position.

The stern seats ready for foam filling. Motor control conduit is PVC pipe.

The bow space is filled with foam and the casting platform hatch drains are fitted.

The stern seats are capped off and the side decks are glued down.

Below, the completed hull, epoxy coated, primed, painted and fitted out! The builder chose a small fuel tank for day trips but a tank can be fitted in the seat box ahead of the console or under a box style helm bench seat.