Shop by Brand

Marissa 18

Construction Album Performance Materials List Builders Logs

The Marissa is a smaller version of our Ocracoke 20 with an easier to build hull shape and a focus on efficiency. The design goal was for the most economical center console boat that would be just big enough to be really practical. By keeping the top end speed at 25 knots the structure could be made lighter which in turn means a smaller motor and less fuel are needed. Calculations show that at 15 knots (17.27 mph) with the 25 hp motor, the 16 gallon (60 liter) fuel tank will give a range of 210 nautical miles in flat water for 15mpg which is more than a lot of pick-ups can do. The top end speed with a 25 hp motor is 21 knots or 24 miles per hour burning 2.2 gallons (8.3liters) an hour. Most builders these days are choose 40-60hp since in many cases the higher hp motors are the same weight since they share the same engine block depending on manufacturer.

LOA………..18′ 0″ 5.49m

LWL………..15′ 3″ 4.65m

BEAM…….. 6′ 10″ 2.08m

DRAFT/ hull.. 8 3/4″ 22cm @ dwl

DEADRISE at transom… 12 degrees

HORSEPOWER…… 25 – 60 (20" motor)

DISPLACEMENT 1680 lbs (764 kilos) @ dwl

Pounds Per I” immersion 335# (152kilos)

Additional measurements:

Cockpit depth measured at the lowest point..... 20 1/4" 51cm

Weight of Hull #1 (seen below) as measured in Aug 2021 including a 40 hp (Tohatsu) motor, 9 gal of gas and normal gear was 1200lbs (544 kilos) with a total weight (boat and trailer) of just 2030lbs.

Trey, a recent Marissa builder sent in this shot of him running his Marissa built from a B&B kit hull #55. Read Trey's Full review here published in the April 2021 issue of Small Boats Monthly. LINK

"My 18' Marissa turned 4 in June and I just wanted to say it still brings a smile to my face the way it slices almost effortlessly through 2' short currituck sound chop. It is the driest boat I've ever had as well as very comfortable in most any direction sea. I don't even have to check the wind forecast before I head out on the sounds because I know, short of a hurricane or other storm it'll be fine. I finally got it dialed in with a brp rogue 13x17 4 blade prop last year and it's as close to perfect as a boat that size can be for me. The fuel economy is stellar as well, 5-6 gallons of gas and I can run all day."

The design was born as an answer to a Wooden Boat design contest. And she won! Read the article below here . This page is reproduced with permission from author Matt Murphy and Wooden Boat Publications. More pictures and video from the design competition here on proboat.com.

The construction method uses developed panels of plywood, built over a jig. This means that hull panels can be full size and will drape over the frame without having to be cut into smaller pieces. All of the “jig” becomes permanent structure. The construction employs a modified “egg crate” method that is both light and strong. The design is aimed at efficiency of materials for performance. We also offer a CNC cut kit for these components for those that want to get a jump start on construction. This is not a stitch and glue “introduction to building" type of boat however it is very suitable for the competent amateur. The Marissa is also an excellent choice for the small commercial yard.

Marissa Plans: Buy Plans

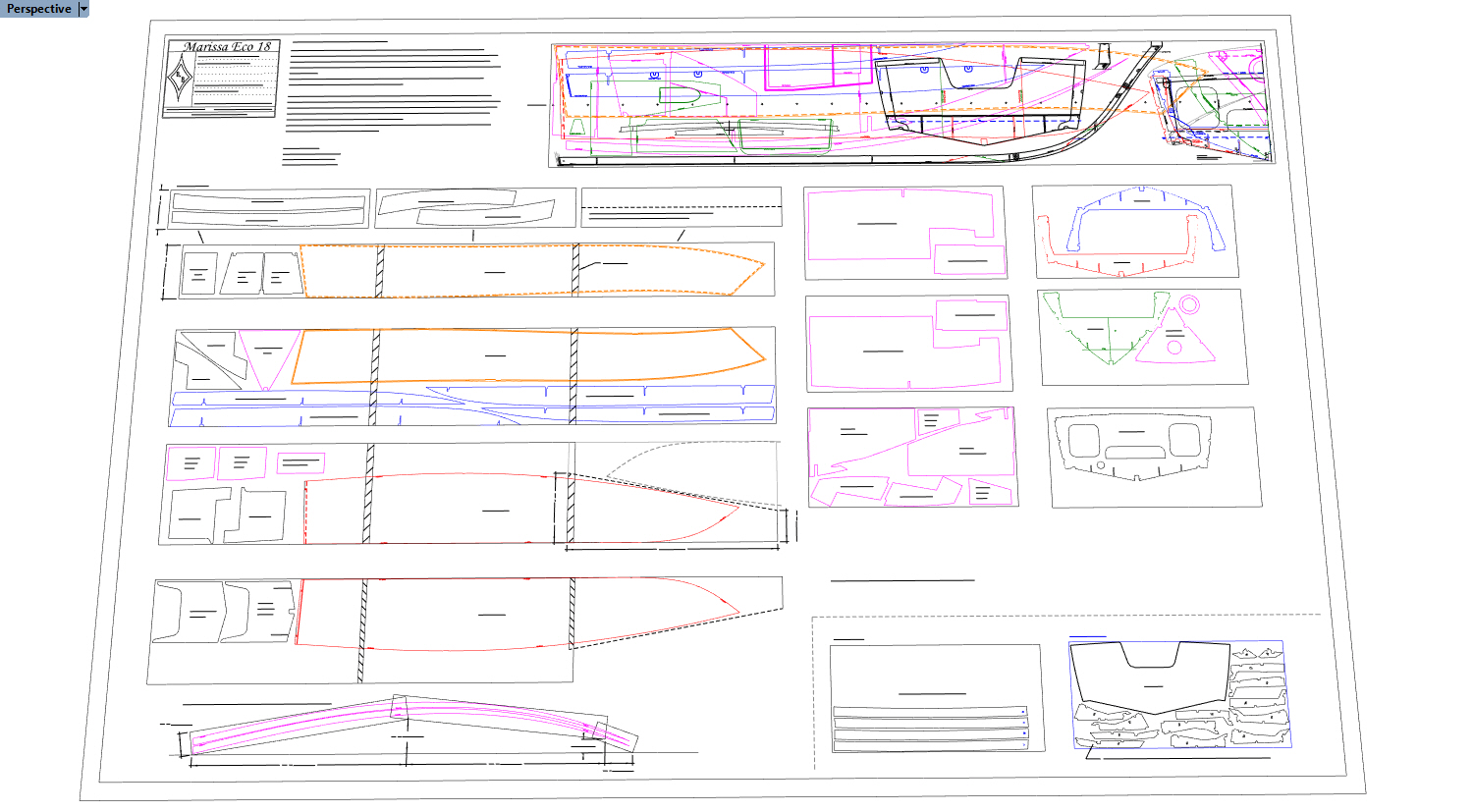

Plans include full size mylar templates for all of the parts in addition to Arch D size prints detailing construction. Below the "template guide sheet" indicates part placement using the templates for good use of materials. Sheets are pre-scarfed prior to cutting out parts from templates.

CNC KIT: For current kit pricing click here

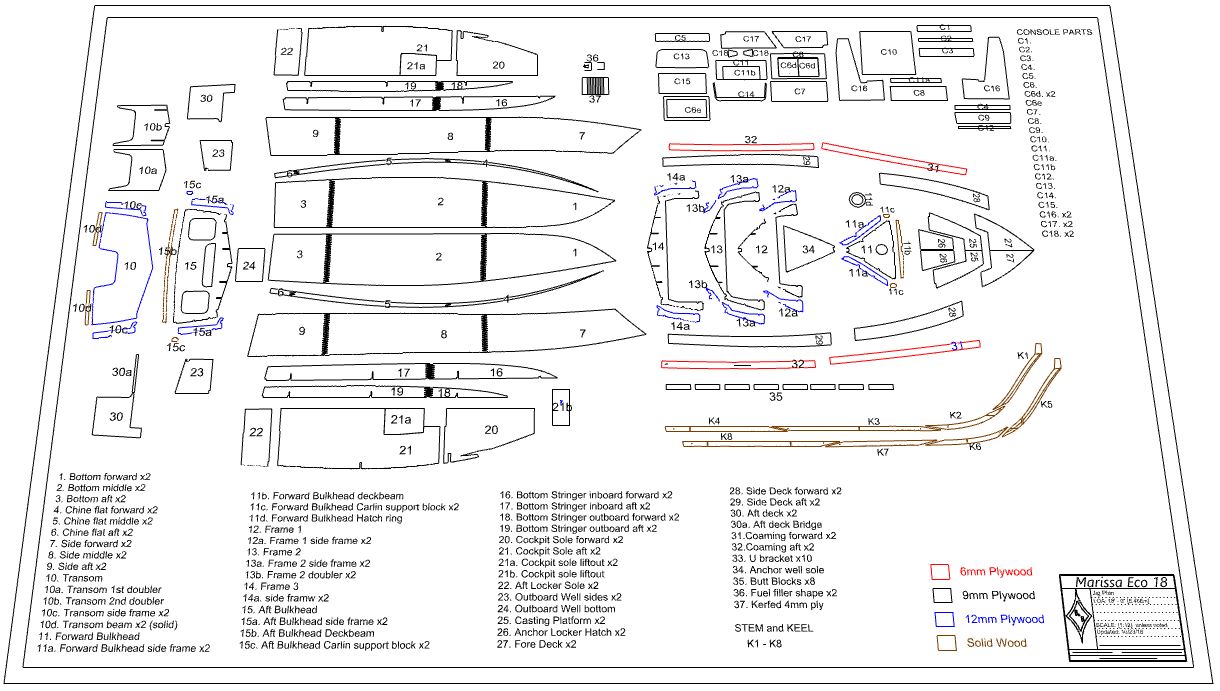

The drawing below shows all of the plywood parts for the Marissa CNC kit. The kit uses 17 sheets of 3/8″ (9mm) 1 sheets of 1/4″ (6mm) and one sheet of 1/2″ (12mm). All plywood is BS1088 Okume. The kit includes all of the hull pieces, (with all frames, stringers, floors etc..) including (shown below) the stem and keel and the center console. Note that the kit incudes some but not all of the solid wood required to complete the build because shipping solid wood in these long lengths is expensive and unnecessary since timber is almost always readily available locally to the builder. These include the side stringers, inwales, rub rails and stiffening cleats. These are locally sourced by the builder, ripped to size and scarfed to length.

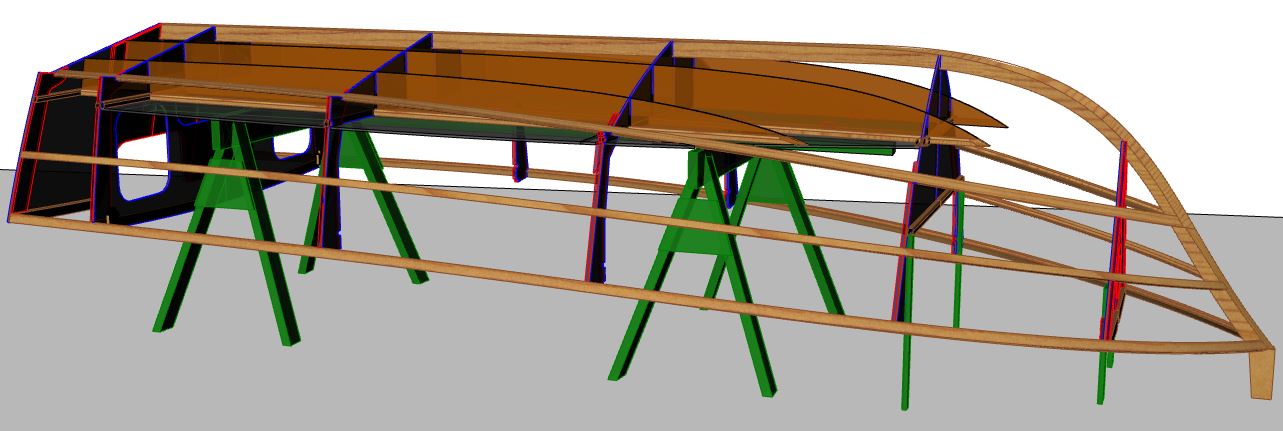

We also offer an epoxy kit consisting of 21 gallons of epoxy, 3 pumps, 2 pounds of colloidal silica, 1 pound of microspheres, glass and tape. The Kit is built on the cockpit sole where the frames fit into slots in the sole and the bottom stringers and keel slot into the frames. Below, the Marisa Jig setup is very modest. A pair of saw horses and a few stiff legs do the job and 2x4 runners support the bulkheads.

Famously, Graham built Hull #1 on two 55 gal drums (below).

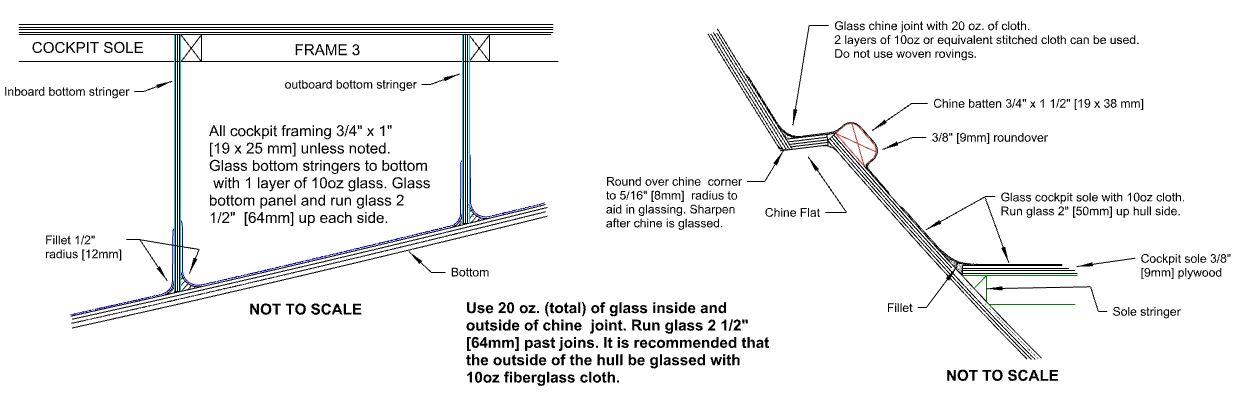

The details below show the unique step chine construction that we developed for this design. Instead of the chine log set “normal” to the side surface as is normally done, we set a chine batten “normal” (flat) to the bottom surface. This eliminates all beveling of the chine and gives a strong anchor to clamp or fasten the bottom to while the epoxy dries. The chine flat shape has been calculated and is machine cut or traced from the full size templates and rests on the frame flats until they are filleted. The side panels lay up to the chine flats and are trimmed to the flats after the glue dries. This method beside being fast to build will make for a very fair chine line and fairs right into the bow eliminating an unsightly unfair bow profile.

Hull #55 receives her flotation foam. The cockpit slopes aft and is self draining through transom scuppers.

This builder added a dual console setup (below) to his Marissa.

Click here to see more pictures of a customized Marissa