Ocracoke 20-B

Latest News: Photos of the first Ocracoke 20-B launched in Australia. Reported 39 knots with a 150 Yamaha.

(New) Builders Guide (slowly updating with helpful information from our builders)

Check out the Builders Logs Library for the Ocracoke 20/20B to see some great build threads.

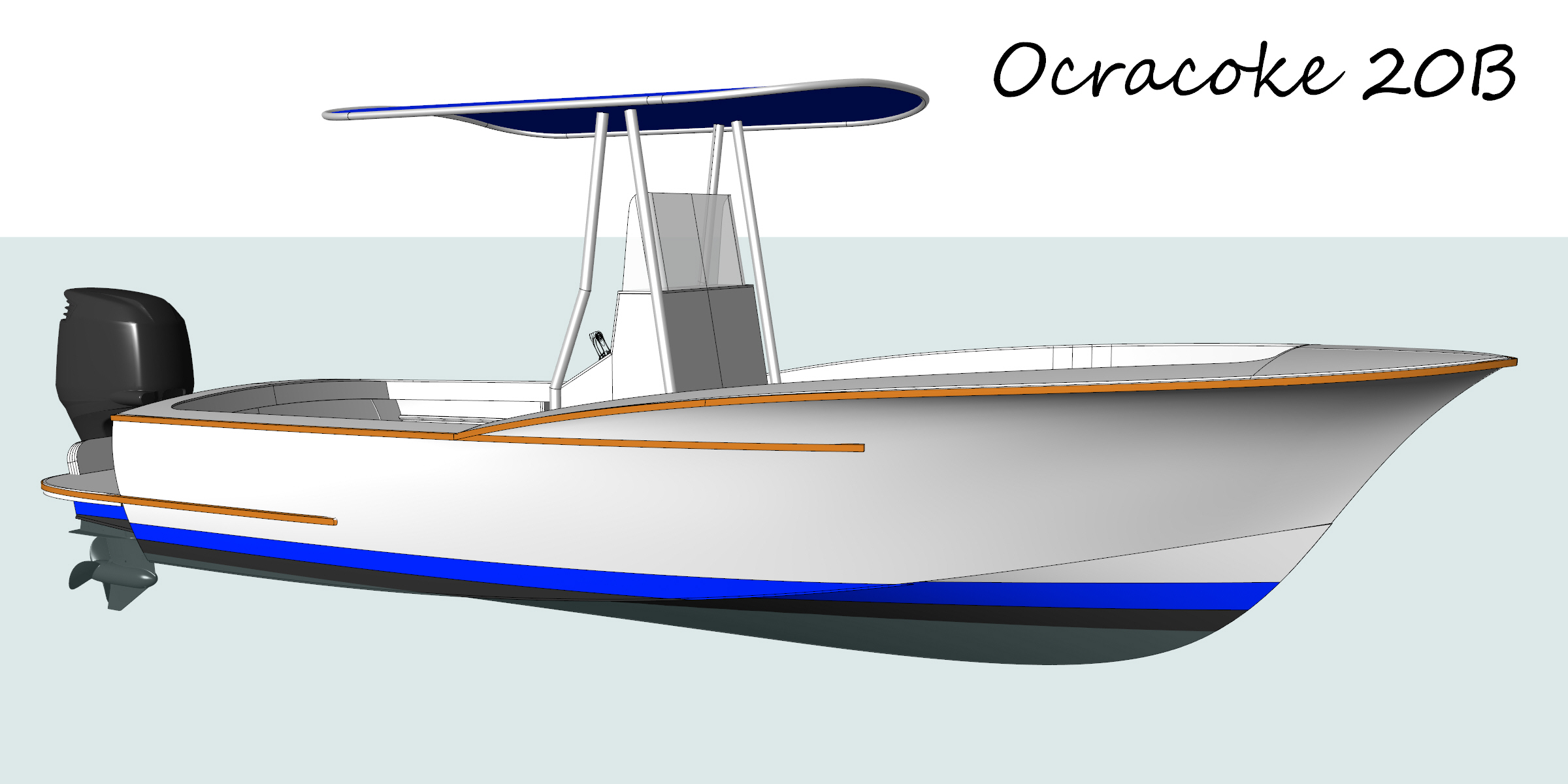

Following the development of the Ocracoke 256, we have had countless requests for a bracketed version of the Ocracoke 20. Well, here she is! The Ocracoke 20B incorporates the same integral bracket as the 256 but in the smaller 20′ package.

We also increased the deadrise to 16 degrees to improve her rough water capability which also helps offset the weight of the motor aft. We’ve incorporated all the bells and whistles in this new kit including optimizing stringer positions to make framing even easier. We’ve also developed a more complete kit with more CNC cut parts to help save even more time on the build. Just like the 20, she is NOT a stitch and glue “introduction to boat building” type of boat and we we don’t recommend this as a first build. However, if you are familiar with working with wood, epoxy, and fiberglass then she should present no problems for the patient builder.

Ocracoke 20B :

LOA (hull)……22′-5″ [6.8m]

LOA (motor)…~24′-9″ [7.5m]

LWL………16′-4” [4.98m]

BEAM………7′-10” [2.39m] overall

DRAFT/ hull………10 7/8″ [27.6 cm] @ DWL

*DISPLACEMENT…2200 lbs (1000 kg) @ DWL

Fuel….47gal

Bare hull weight ~1550lbs (703 kg)

Dry Weight including 90 hp motor…~1900lbs (861 kg) depending on materials and options*

Pounds Per I” immersion 425lbs (193kilos)

Deadrise at transom… 16 degrees

Horsepower… 90 recommended , 150 (max)

*weight @ designer’s suggested materials; different plywoods and/or different fiberglass weight and optional gear will change boat weight.

NEW: Click here to download the WEIGHT STUDY Spreadsheet where you can see how the boat will trim with different motors. DWL is with 90hp motor. Larger motors will change trim angle!

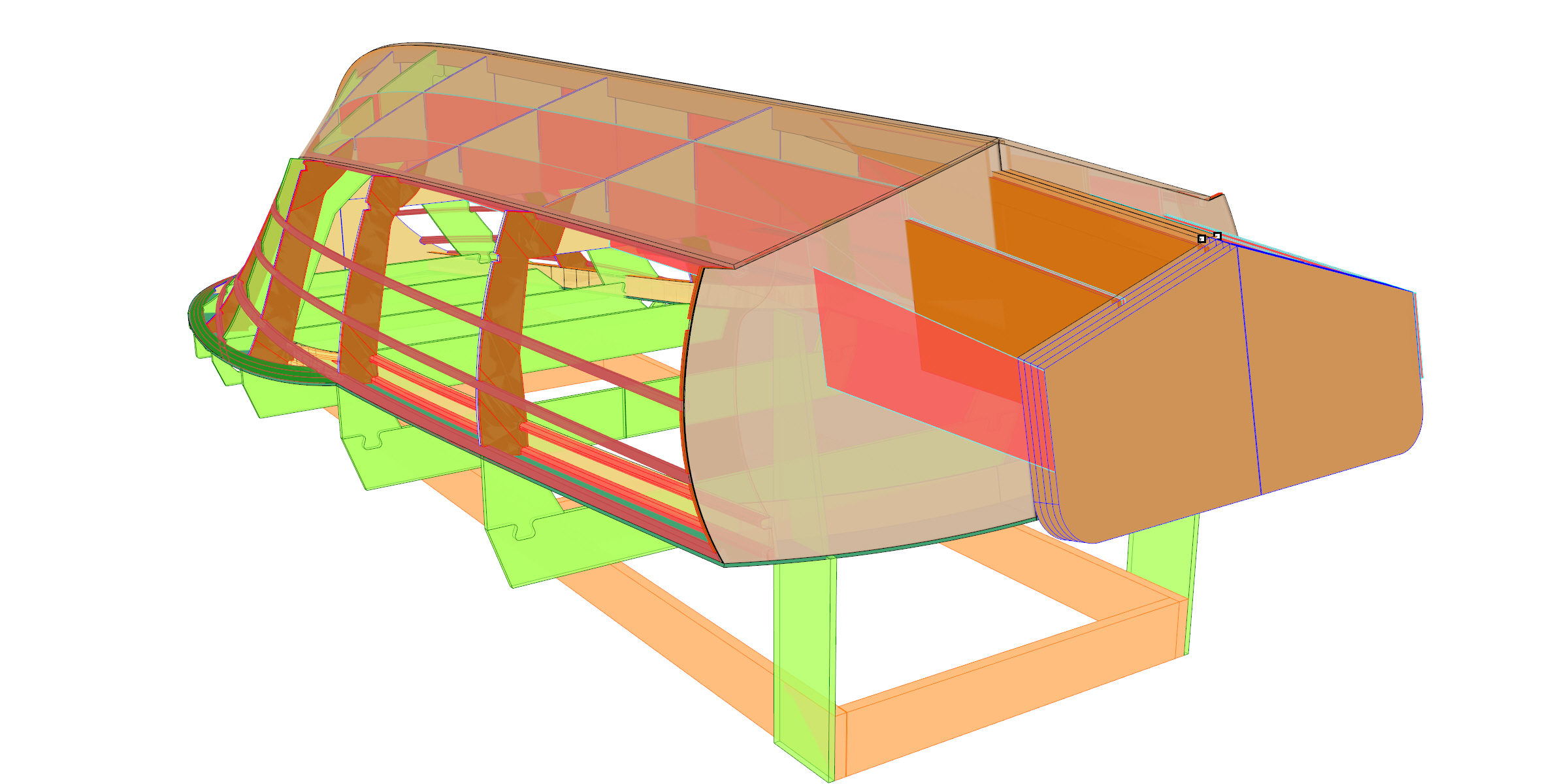

Construction techniques for the 20-B are identical to that of the Ocracoke 20. The main difference is that the bottom stringers extend through cutouts in the transom to form webs for the integral bracket. The first, third and fifth frames are temporary jig frames. A cant frame at the bow keeps the sheer clamp in check and at the proper curvature. All of the rest of the structure stays in the boat when flipped as permanent structure.

CNC kit:

CNC cut kits are available directly from B&B. Current kit pricing is shown below. Kits are only available in the US and Canada. See our shipping policies for more information on shipping a kit.

JIG KIT:

The Jig Kit is intended for a builder that perhaps already has plywood on hand with which to plank the boat such as a commercial yard OR one who intends to customize the interior and doesn't need the cnc cut decks or cockpit sole. The jig kit includes...

-CNC cut 12mm okoume bulkheads, bracket webs, and 9mm okoume bottom stringers

CNC cut 3/4" Birch ply temporary frames and transom camber forms.

-CNC cut Transom layers (3 laminated layers of 4mm okoume)

-CNC cut Southern Yellow Pine keel, stem and horn timbers. Ready to glue up with bearding line and bulkheads marked.

-CNC cut 12mm okoume chine flats with finger scarfs.

-CNC cut Bracket Transom layers (4 layers of 18mm meranti)

Planking and Decks Kit:

This option includes parts that could be cut to fit the boat from bare sheets to save the extra cost of CNC cutting but for most builders we think this should be considered a necessary option.

The planking and decks kit includes...

-CNC cut 12mm okoume and 6mm okoume for the forward and aft bottom planking.

-CNC cut 12mm okoume swim platform and bracket bottom. (the main bracket structure is in the jig kit)

-CNC cut 9mm okoume cockpit sole panels, aft deck, side deck, foredeck

Side Planking:

The side is not CNC cut. It consists of 9 sheets of 4mm okoume which are ripped lengthwise in order to fit them into our 4' x 8' shipping crate with corner braces. These sheets are eventually ripped into 6-24" wide strips to be used to plank the topsides with 2 layers (8mm total) using the ashcroft method. This is offered as an option only because some builders may already have a source for 4mm okoume or have it already on hand such as a commercial yard and therefore can save the cost of shipping these sheets.

CNC Console Kit:

The console kit consists of all the parts to produce the 9mm okoume plywood console detailed in the plans with a lifting forward seat with integral drain channel, toe kick and butterfly door access panel on the aft side below the helm.

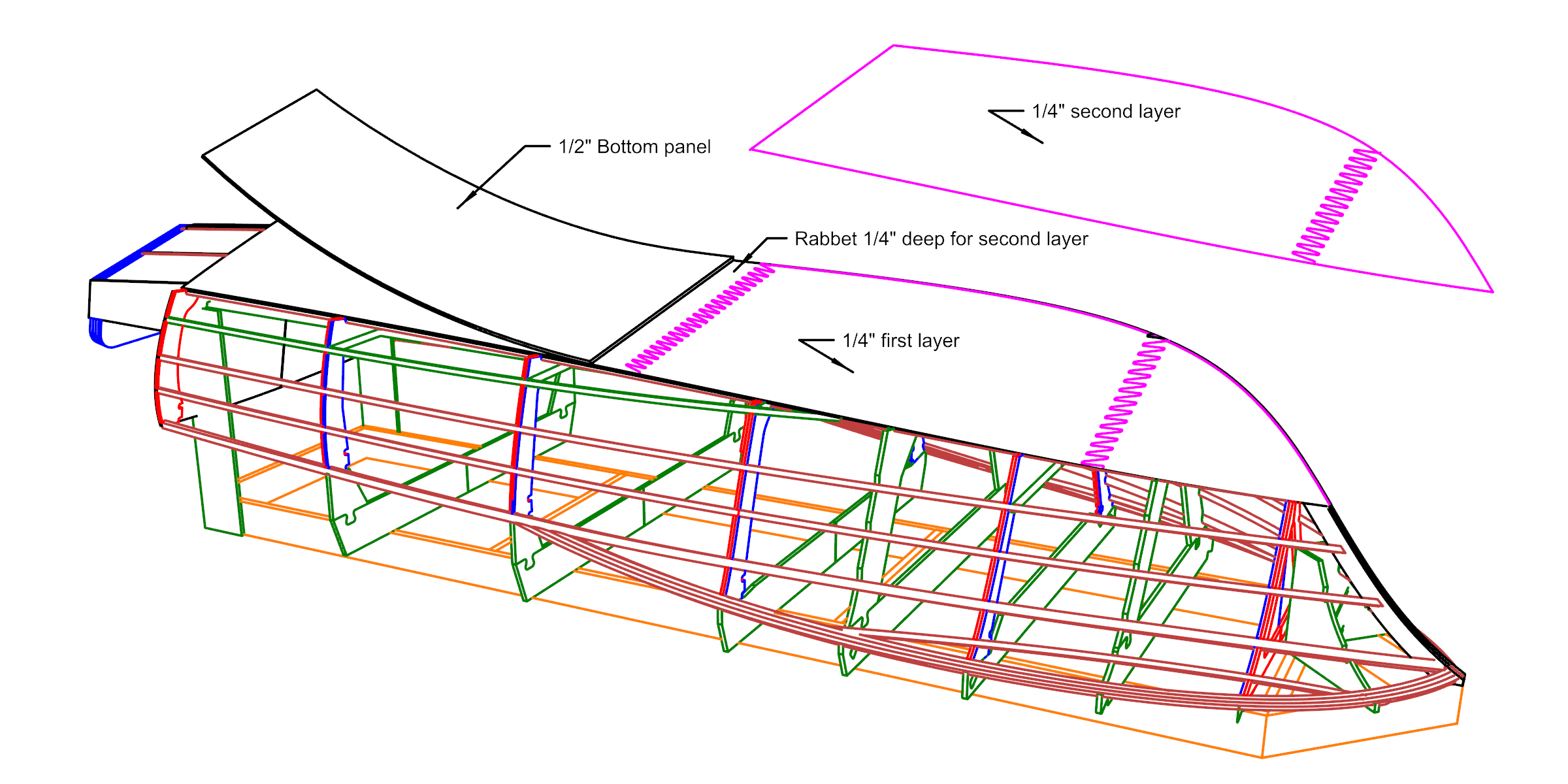

The bottom of the hull is planked with a single layer of 1/2″ (12mm) plywood in the aft sections and 2 layers of 1/4″ (6mm) ply with staggered seams in the forward section. The developed bottom shape means that the bottom panel is glued down in one piece (bent over the jig) followed by the second layer of planking forward. (Picture below as shown on planking plan).The sides are planked with two layers of 3/16″ (4mm) ply using the Ashcroft method which means both layers run diagonally in the same direction, the seams in the two layers are staggered.

The entire boat is epoxy and fiber-glassed inside and out which makes for a very strong tough structure. The complete encapsulation of the wood creates a very low maintenance and a long-lived boat. Epoxy primer and 2 part polyurethane provide an extremely durable finish.