Product Description

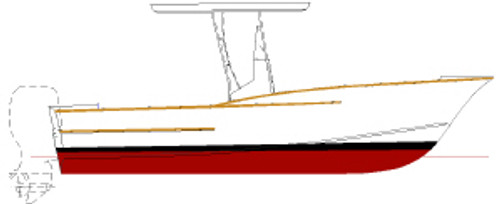

Originally designed in conjunction with the late Capt. Hugh (Buck) Wilde and Diamond City Boatworks in Beaufort, NC in 2008 hull #1 named "NAD 28" is seen pictured below. You can read about this project on the hull truth forum here. The boat was fitted with twin 300s and topped out at a respectable 47 knots (54mph). Buck noted that she could have been built lighter but was dressed with solid teak decking. He also felt that with more prop tuning and motor adjustment 60 mph would have been achievable.

We have developed a kit for the boat with some slight tweaks. The original was built with a plywood bottom and strip planked sides. We have since converted to cold molded sides as we feel this is an easier method for most builders. We have also increased the dead-rise by 1 deg from the original hull to 19. See below for construction details, plan and kit pricing. You can download a current complete estimate for the kit and the materials list at the bottom of the page.

Click here to see an album of construction pictures of hull #1.

Cape Lookout 28 specs :

LOA (hull + bracket)……30′-8″ [9.344]m

LWL………23′-0 3/4″ [7.029]m

BEAM………10′-0″ [3.051]m overall

DRAFT/ hull………17″ [43 cm] @ DWL

Deadrise at transom… 19 degrees

*DISPLACEMENT…6000 lbs (2720 kg) @ DWL

Pounds/kg Per 1” immersion 760# (345 KG)

Fuel Capacity….250 gal

Horsepower… 600 (max)

*weight @ designer’s suggested materials; different plywoods and/or different fiberglass weight and optional gear will change boat weight.

Bare hull weight ~3,000 lbs (1,360 kg)

DRY weight including TWIN 300 hp motor…..4100-4500 lbs (1860-2040 kilos) depending on materials and options*

Displacement at full tank capacity ~6000 lbs (2725 KG) @ DWL

*weight @ designer’s suggested materials; different plywoods plus different fiberglass weight and optional gear will change boat weight.

Construction Details:

The boat and jig kit as described here is designed for plywood/epoxy construction. This proven method produces a strong light hull with excellent stiffness and takes advantage of the accuracy of CNC cut parts. The complete encapsulation of the wood with epoxy creates a very low maintenance and a long-lived boat. Epoxy primer and 2 part polyurethane provide an extremely durable finish.

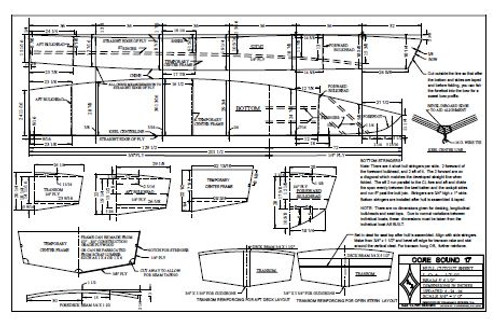

Above: Note green temporary frames which are removed after the boat is flipped. The Jig kit includes a "Jig Base" as shown which locates the temp frames. The jig base is leveled on the shop floor to create a flat plane. Alternatively the boat can built on a traditional strong back type jig frame.

Once the jig structure is assembled and the keel, side stringers and sheer clamp are installed the bottom is planked followed by the integral chine flat. The sides are cold molded in 2 layers of 6mm marine plywood using the Ashcroft method in which both layers run diagonally in the same direction, the seams in the two layers are staggered.. An integral bracket creates an incredibly strong structure. The plywood bottom stringers extend through cutouts in the transom to form webs for the bracket. The developed bottom shape means that the bottom can be planked with full size plywood panels.

All the wood structure is coated in epoxy to protect it from moisture. The outside of the hull is faired and fiberglassed prior to flipping.

Above: Hull #2 planked and ready for final fairing and fiberglass. Photo Credit: Steve Palmer

More pictures of hull #2 will be available soon.

Right click on images below and open in new tab for larger view.

Frequently Asked Questions and modifications:

Due to the endless customization and options of a boat this size we have tried to provide all the information the builder will need to produce a strong and good performing hull. Allowances have been made for normal options however construction details are not provided at this time for things such as built in fish boxes or bow seating. The cockpit is drawn as a single level but a step up or bow seating can easily be added by the builder.

Can I use an inboard motor? or Have you designed it for an inboard?

No, not at this time. This design is specific to outboards. We would like to offer this design for an inboard but there is a lot of design time that goes into each design and we're just waiting for the right builder(s) who would like to fund this modification. If we get enough interest by builders wanting an inboard version we will certainly get it done.

Plywood is nice but I want to build it in foam can I use foam?

Note that one of the advantages of cold molding is all of the permanent structure which is already built into the jig. Once the boat is flipped all of the bottom structure is already in place. With a foam hull everything must come out after the boat is flipped (the whole jig is temporary) so the that inside skin laminate can be applied. Bulkheads and stringers are then put into the hull. This method uses a lot more material for the jig which may not be reusable due to the tumblehome in the stern of the boat which prevents the boat from simply lifting off the jig. That said, if you would like a cnc jig for the boat to use for foam construction, contact us and we can provide pricing for the design changes and jig design for all temp. frames and battens needed for foam planking.

Pricing

Study Plans: $45.00 (available in hardcopy only)

Full Construction Plans including Full size Templates: $450.00

All plan sheets for construction plus full size mylar templates (mylar templates are taped together lengthwise using strike up marks on 12″ centers and used to transfer frames and jig shapes to plywood) Plan sheets include 16 x ARCH D size full color construction drawings showing every detail of construction. Study Plans are simply smaller 11×17 print outs of all of the plan sheets and of course do not include the templates. There is no table of offsets because the full size templates make them redundant. Trace the parts directly onto your plywood and cut out with a jig saw. Included are full size outlines for all of the parts that we offer in the CNC kit. The frames and bulkheads and drawn with the notches located and sized for the side stringers. Stations are given in halves. When tracing your parts on the wood you will simply flip the patterns or make a scrap template to mirror the frame outline for port/starboard. The use of the template patterns eliminates any need for lofting and ensures that your framework will be accurate and true.

*Mylar is drafting film, which while expensive, is totally stable and practically tear proof. It is practically transparent, making it easy to orient on your plywood grain and allows for it to be used for both sides on one sheet. Paper templates of this size would change too much with changes in humidity.

Jig Kit: $6,200

The CL-28 Jig Kit includes all plan sheets and all CNC cut parts listed below. All temporary frames are cut from 3/4" Birch Plywood and all permanent structure is Okume or Meranti BS1088 marine plywood. We only use the highest quality plywood we can find. Contact us for pictures of our stock if you like or to compare with local sources as not all marine plywood is created equal.

Jig Kit includes:

All permanent and temporary bulkheads/jig frames and jig base (as shown above). Plywood bottom stringers, chine flat (reverse chine), transom lamination layers, transom camber jig, bracket transom lamination layers and jig for laminating the stem.

The jig kit is designed to jump start the build allowing the builder to start with accurately cut frames and bottom stringers onto which to lay side stringers and get on to planking as fast as possible. This is not a complete kit.

Jig Kit does NOT include:

Plywood need for planking the hull sides or bottom.

Plywood needed for the cockpit sole, fore-deck or side deck.

Solid timber for hull side stringers, gunwales, Inwales, Carlin or keel and stem.

Plywood parts for center console or leaning post.

Hull Planking and additional Plywood:

We can supply the additional plywood needed to complete the hull. We also sell epoxy and can supply fiberglass products. These are typically drop shipped in larger quantities. Click the button below for a current estimate for the CL-28 Jig Kit and additional plywood materials. Solid timber for stringers and keel should still be sourced locally.

Click the button below to see the materials list for the CL-28.