Builders Logs (lots of pictures)

Materials List (Download)

Ocracoke 256 Hull #3 launched in October 2017. More pictures

Ocracoke 256 Hull #3 launched in October 2017. More pictures

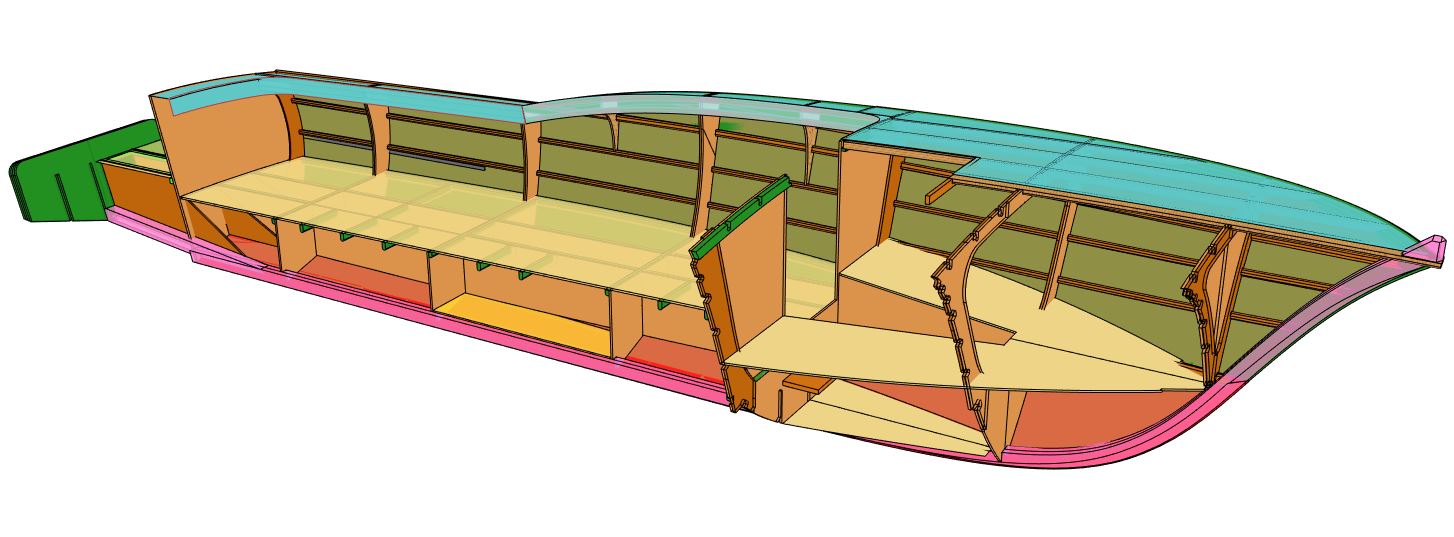

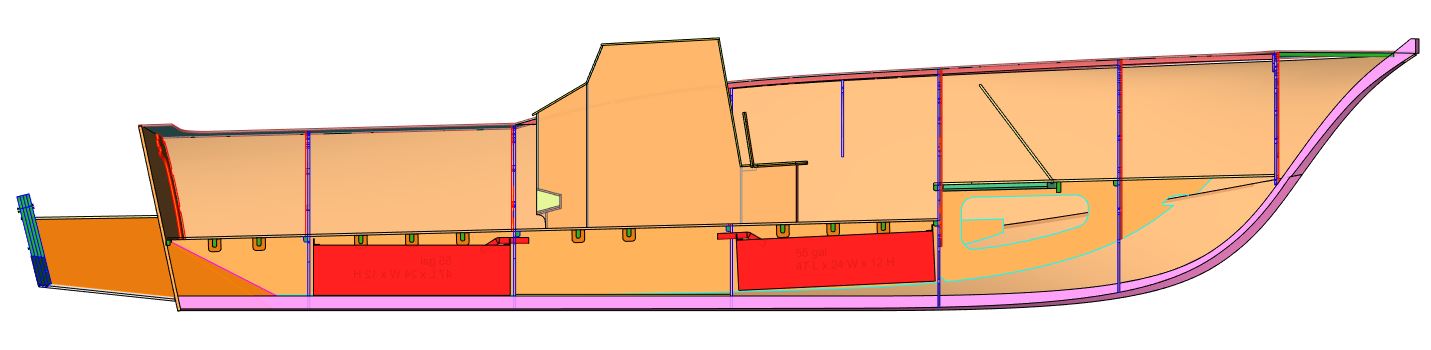

The 256 is an exciting addition to B&B’s Ocracoke line of powerboats released in October 2015. We have spent many many hours developing every aspect of her construction with the home builder in mind. At 25' 6" she is the second largest Carolina Style design we offer plans for. Need bigger? Check out the Cape Lookout 28.

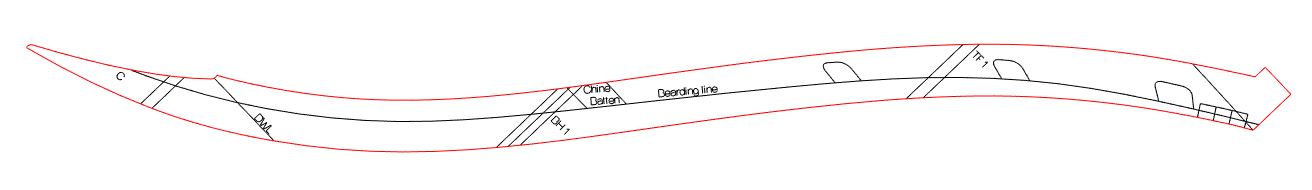

Length on deck……25′-6″

LWL………21′-2 1⁄4” [6.386] m

BEAM………8′-6″ [2.590] m (Trailer-able width)

DRAFT/ hull………13 5⁄8” [34.6] cm @ DWL

Dry Weight (without engines)………2700 lbs

(1225 kilos)

*DISPLACEMENT………3300 lbs (1497 kilos) @ DWL

**Max horsepower……300

Deadrise… 16 degrees

"Sheila B" Built by John and Katrina in Vanuatu.

All Plan sheets are printed on Architectural “D” (24″x36″) paper. Detailed plans consist of the 8 sheets shown below which detail all aspects of construction.

Kit Options: Click to View current kit pricing

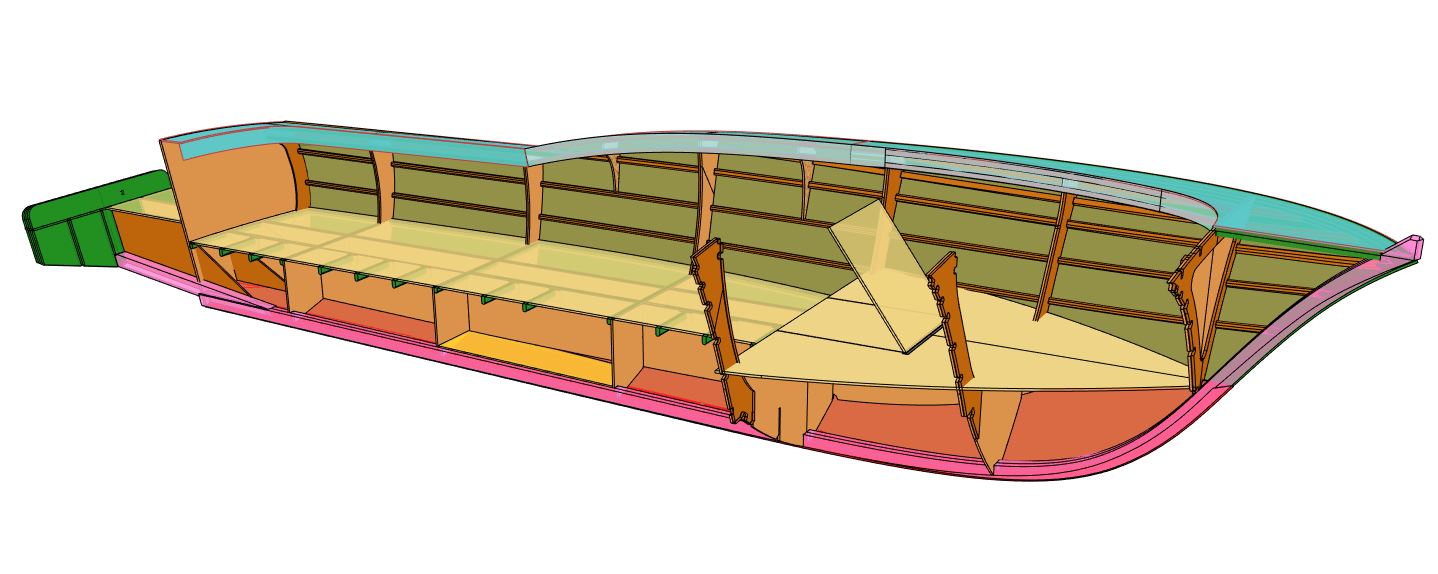

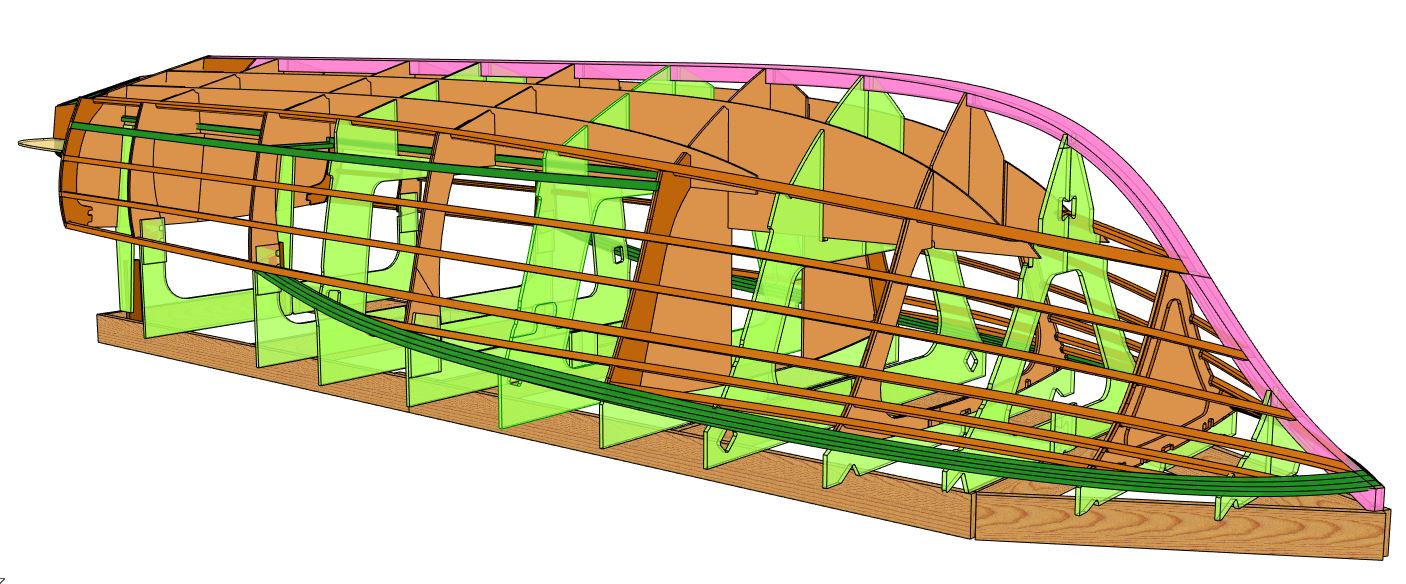

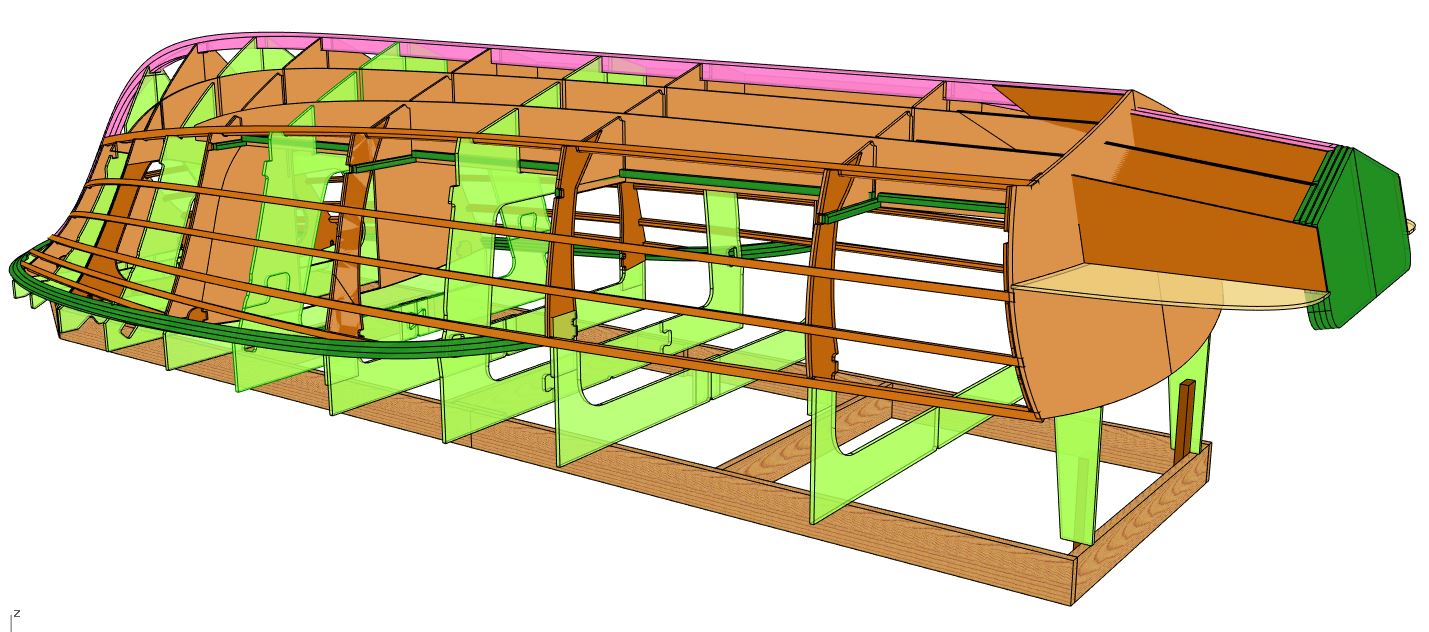

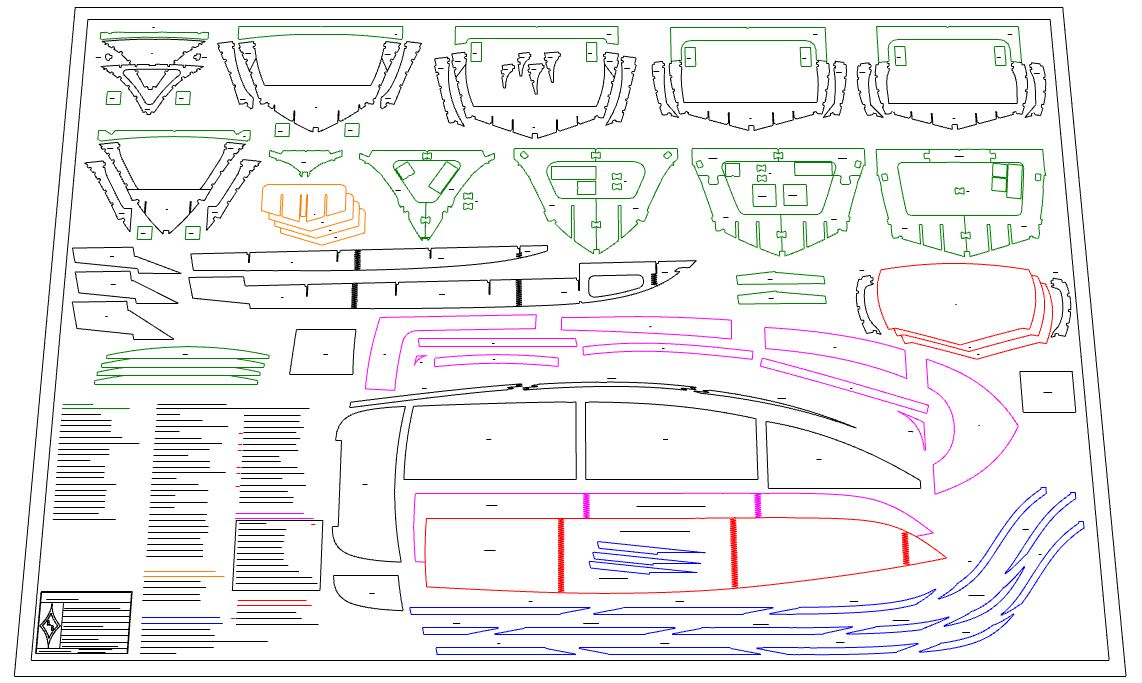

The Jig kit is our basic CNC cut hull kit to get the boat "jigged up" in no time flat. It is not a complete kit and does not include all of the plywood needed for construction but is a great option if you have plywood available locally and want to save on shipping the raw materials for planking. The CNC cut parts included are:

- Southern yellow pine keel/stem.

- Permanent and temporary frames for jig construction.

- Plywood bottom stringers.

- Transom laminations.

- Bracket components.

- Chine flats.

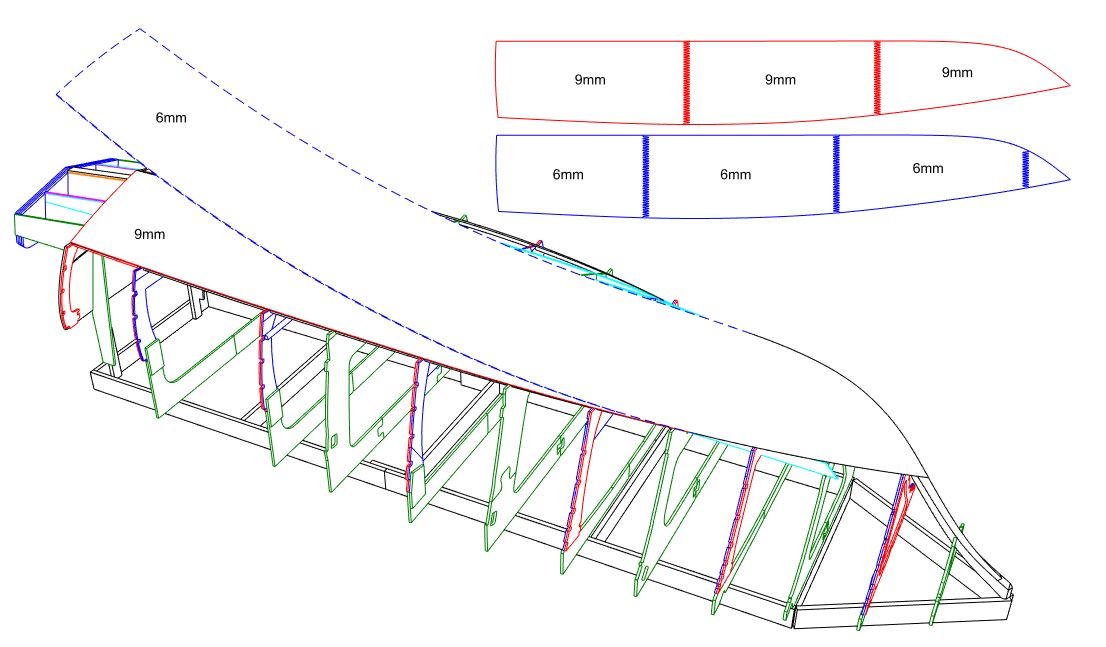

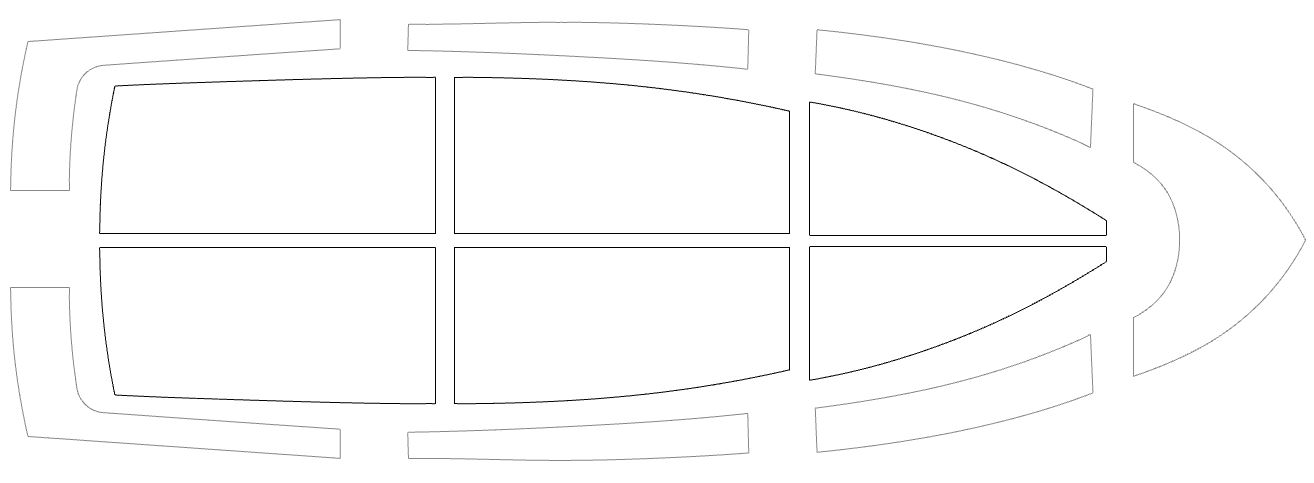

Below, the kit parts sheet shows the parts of the jig kit along with the optional CNC cut cockpit sole and decks. Parts in Green are temporary frames. All parts are numbered and clearly identified.

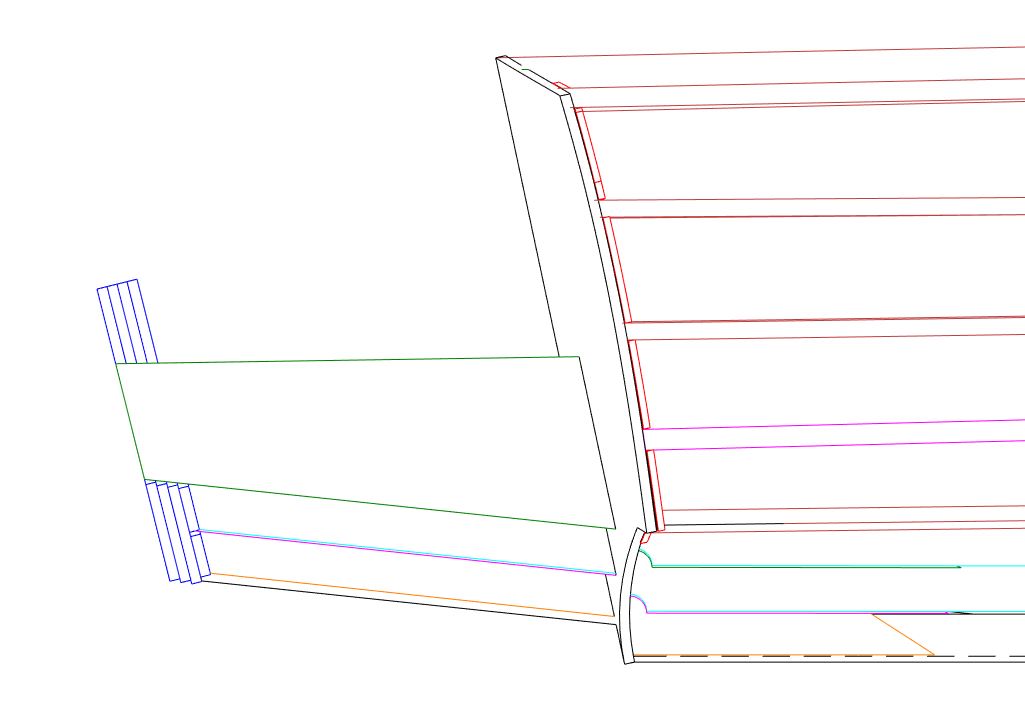

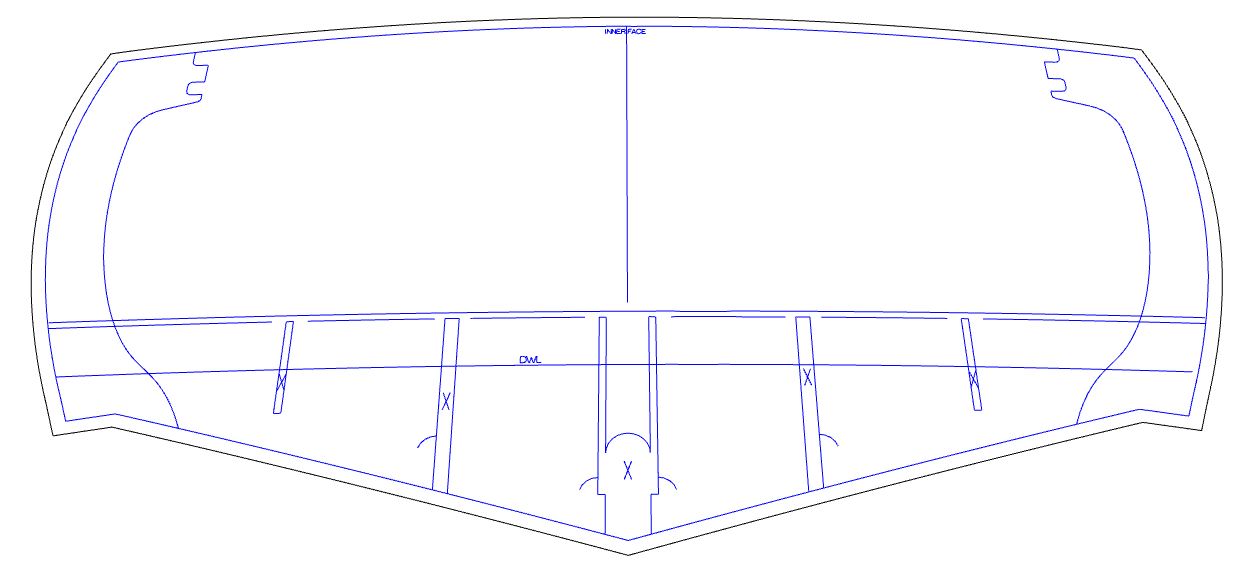

Below, The CNC cut Transom is constructed of 3 layers laminated over a camber jig. Blue lines shown below are drawn by CNC machine indicating the location of bottom stringers, cockpit sole and frame doublers making assembly and alignment of a complex part a straightforward operation.

Additional Plywood: If you don't have a good source of plywood to finish out the jig kit this option adds all the extra sheets you'll need to plank the the boat as well as material for the cockpit sole and decks.

What else will I need? In addition to the jig kit and additional plywood. You will need to source....

Dimensional Lumber (2x8) used to build the Jig Base or Strongback. Solid wood for side stringers, chine batten and sheer clamp. These are easily ripped up by the builder using locally sourced material and scarfed together to the length required. Epoxy, which can be supplied by B&B as well as fillers and pumps. Fiberglass cloth for reinforcing the hull.

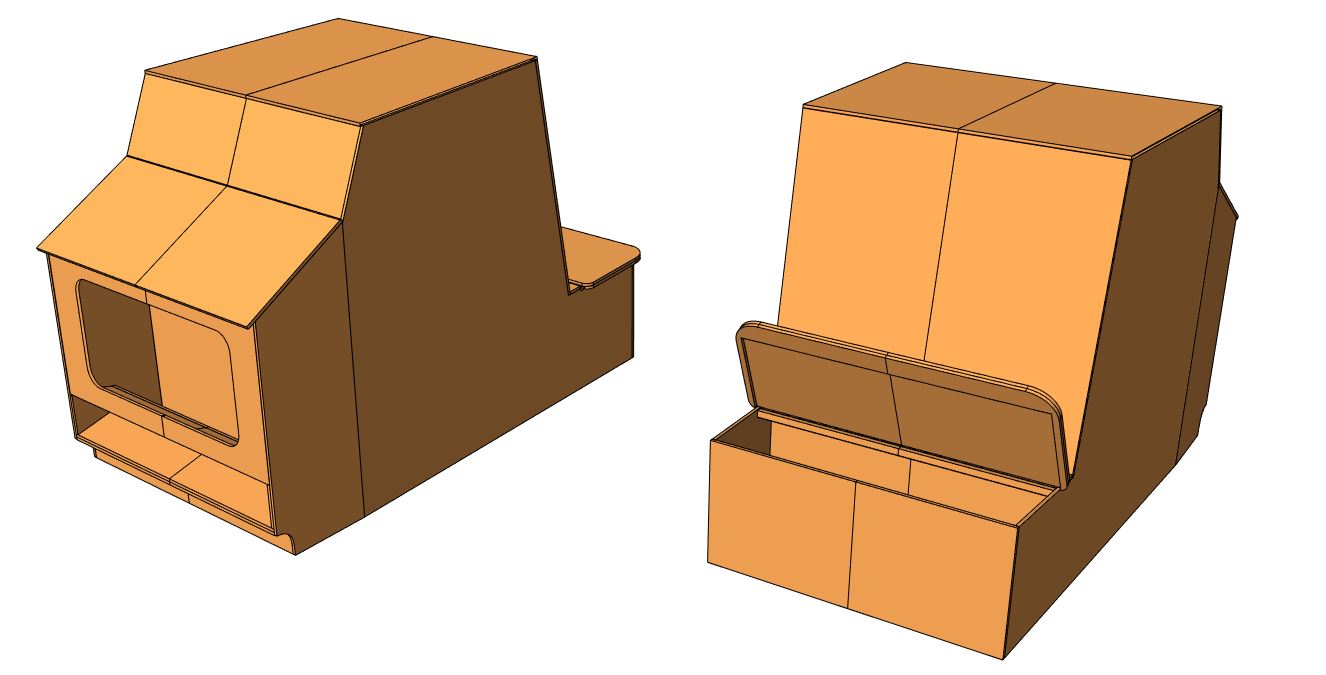

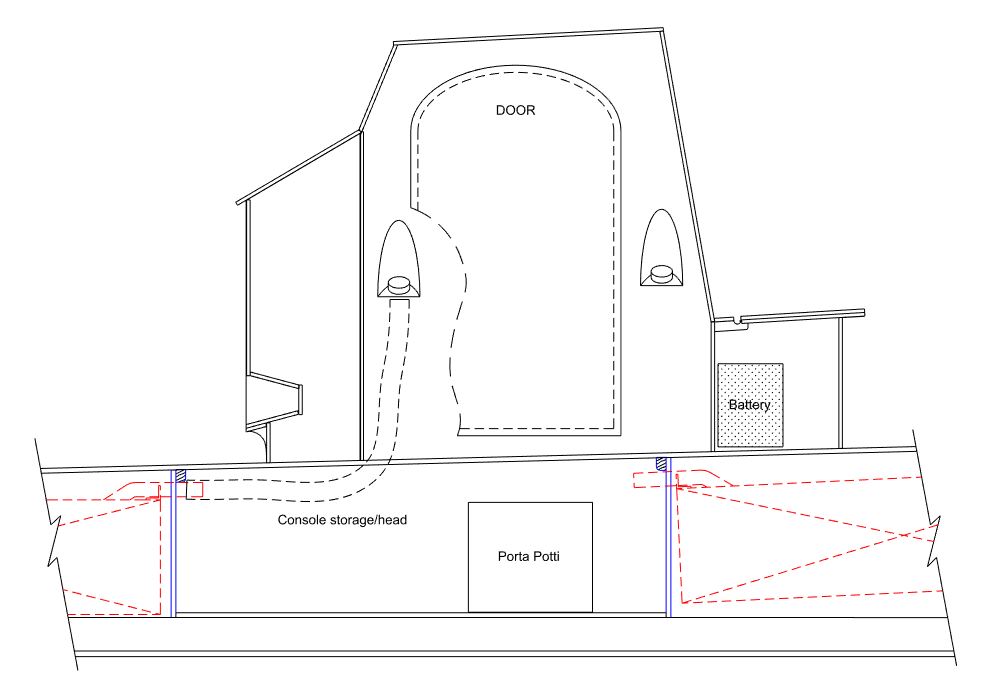

Additional CNC cut parts option: For those who want even more pre-cut parts, this add on option includes the 12mm cockpit sole CNC cut to rough size to make it easier to fit into the boat and the 9mm deck parts cut slightly oversize for final install and trimming. These parts would otherwise be patterned off of the boat "as built".

Additionally, the bottom planking is cut to rough size with our "finger joint" scarfing method, this option saves the builder the time of scarfing and fitting the bottom planking.